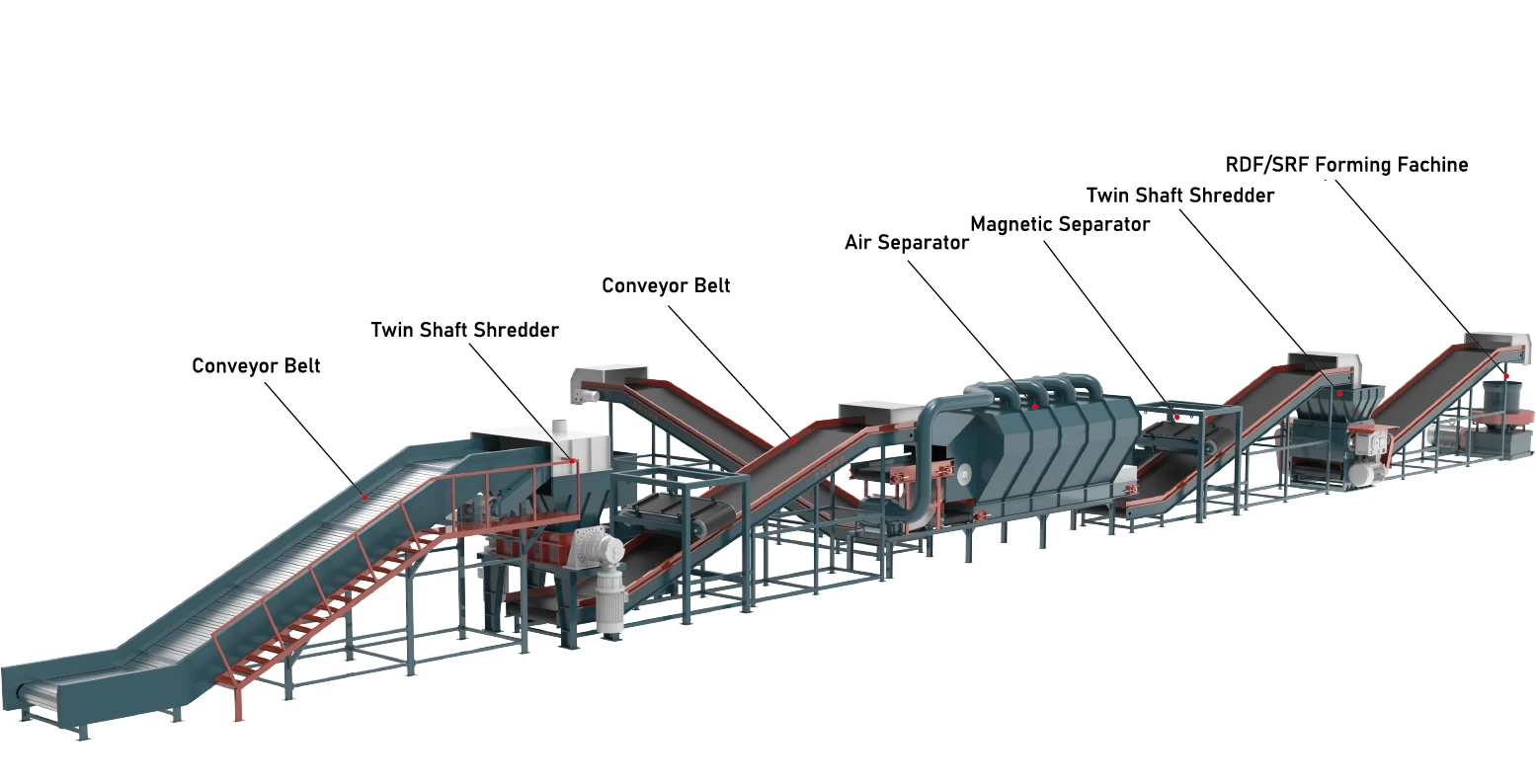

Standardized Production Process of Industrial Solid Waste Shredder Production Line Raw Material Feeding and Pretreatment

Bulk, bundled and block industrial solid waste is fed into the shredder's cutter box via a belt conveyor. For large-sized and hard mixed waste, simple disassembly and sorting by manual labor or a shearing machine are required to remove hard objects that the shredder cannot process, so as to avoid damage to the shredder's cutter set.

Shredding Process

The pretreated materials are fed into the shredder's knife box, and primary shredding is completed through the shearing, tearing and extrusion of the moving blades and fixed blades. If the materials require fine shredding, the coarsely shredded materials are conveyed to the crusher via a conveyor belt for secondary crushing.

Sorting and Impurity Removal

The crushed materials are conveyed to the sorting unit via a conveyor belt, and the sorting equipment is selected according to the type of waste: magnetic separators are used to separate ferromagnetic metals from mixed metal and non-metal waste; air separators/density separators are applied to separate mixed plastic and rubber waste; screening machines are adopted for sorting mixed paper and impurity waste. Meanwhile, the dust generated during the production line operation is collected by pulse dust collectors.

Core Configuration of the Production Line

For soft solid waste (plastics, rubber, paper), a double-shaft shredder is preferred as the main unit, featuring strong shearing force and resistance to material adhesion on blades. For hard solid waste (metal, wood, thick-walled pipes), a four-shaft shredder is the optimal choice, which offers excellent pressure and impact resistance with high shredding efficiency. Large-scale processing lines are equipped with a PLC automatic control system, enabling remote operation, feeding speed adjustment and equipment fault alarm. This reduces manual intervention and improves operational efficiency significantly.

Functions of the Industrial Solid Waste Shredder Production Line

Industrial solid waste (such as large plastic parts, wood offcuts, and metal scrap) is characterized by a large original volume and high costs for transportation and landfill disposal. After being processed by a shredder production line, the volume of the material can be reduced by 50%-90%, which drastically cuts down the number of transportation trips and the land area required for landfills, and lowers the overall cost of solid waste disposal for enterprises.