Pre-treatment Stage Sorting & Dismantling The collected waste lithium battery packs (e.g., power batteries, consumer batteries) are first manually sorted to remove impurities such as plastic casings, connecting wire harnesses and metal brackets.

Automatic dismantling machines disassemble the module casings of battery packs via robotic arms to separate individual lithium batteries; for small-sized consumer batteries (e.g., mobile phone batteries), they are directly transferred to the next stage of the process.

The disassembled individual batteries are classified by type (ternary lithium batteries, lithium iron phosphate batteries), and batteries of different systems are processed separately.

During the disassembly process, avoid squeezing or piercing the battery to prevent short circuits and fires.

Discharge Treatment

The individual battery is immersed in a neutral salt solution (e.g., sodium sulfate solution) for low-temperature constant-temperature discharge, until the residual voltage drops below 0V.

For large-capacity power batteries, a resistive discharge cabinet is adopted for forced discharge. The voltage is monitored in real time during the discharge process to avoid battery bulging caused by over-discharge.

The residual voltage of the battery after discharge shall be ≤ 0.05V; the temperature of the discharge environment shall be controlled within the range of 20–30℃ to prevent the electrolyte from volatilizing due to heating.

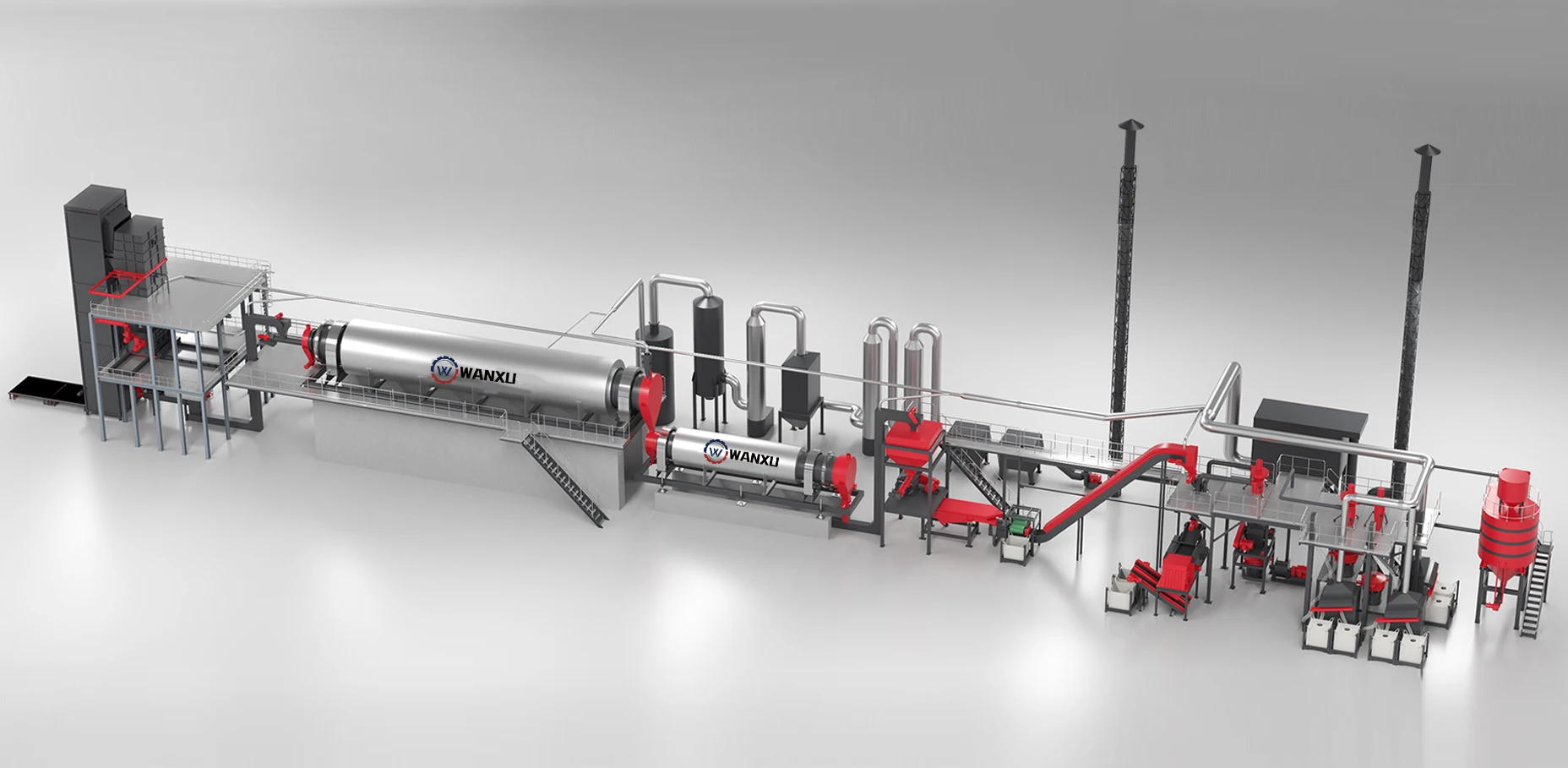

Crushing & Disassembly

The discharged batteries are fed into the twin-shaft shredder via the conveyor belt and shredded into small pieces of 5–10 cm. Then they are transferred to the crusher through the conveyor belt for further size reduction into 1–2 cm particles. Meanwhile, the negative pressure system is used to collect the electrolyte vapor volatilized during the shredding process.

The electrolyte recovery rate can reach over 90%.

The entire shredding process must be carried out in an inert gas atmosphere to prevent the metal powder from spontaneous combustion.

Physical Separation Stage

Low-temperature Pyrolysis

The crushed battery particles are fed into the rotary kiln and roasted at a low temperature of 300–400℃ in an oxygen-free atmosphere.

The electrolyte (an organic solvent) volatilizes when heated and is recovered through condensation; the separator (polyethylene/polypropylene) decomposes into gas upon heating and is discharged after purification by the tail gas treatment system; the binder carbonizes and loses its adhesiveness, causing the positive and negative electrode active materials to separate from the current collectors.

The calcination temperature is strictly controlled to prevent it from exceeding 450℃, which would cause lattice damage to the cathode materials; the exhaust gas shall meet the VOCs emission standards after purification.

Screening & Magnetic Separation

The calcined material is first classified by a vibrating screen to separate the large-sized metal sheets (copper foil and aluminum foil) from the fine positive and negative electrode powders.

The metal sheets are then fed into a high-intensity magnetic separator, which separates the magnetic copper foil from the non-magnetic aluminum foil; both metals are collected separately for recycling.

The fine powders pass through an air classifier, where the lightweight anode graphite powder is separated from the heavy cathode active powder (e.g., ternary materials, lithium iron phosphate) by virtue of density differences.

Chemical Purification & Regeneration Stage

Cathode Material Leaching

The calcined material is first classified by a vibrating screen to separate the large-sized metal sheets (copper foil and aluminum foil) from the fine positive and negative electrode powders.

The metal sheets are then fed into a high-intensity magnetic separator, which separates the magnetic copper foil from the non-magnetic aluminum foil; both metals are collected separately for recycling.

The fine powders pass through an air classifier, where the lightweight anode graphite powder is separated from the heavy cathode active powder (e.g., ternary materials, lithium iron phosphate) by virtue of density differences.

Chemical Purification & Regeneration Stage

Cathode Material Leaching

The cathode powder and the leaching agent (sulfuric acid + hydrogen peroxide system or organic acid system) are added to the reaction kettle in proportion, followed by a constant-temperature stirring reaction.

The metal ions (Li⁺, Co²⁺, Ni²⁺, Mn²⁺) in the cathode material dissolve into the liquid phase, while insoluble impurities (such as carbon powder) form filter residue.

After the reaction is completed, the leachate and filter residue are separated by a plate-and-frame filter press. The filter residue is subjected to harmless treatment after washing.

Solution Purification

The leachate is subjected to solvent extraction, where extractants are used to selectively separate cobalt, nickel and manganese ions, achieving the mutual separation of the three metals.

A precipitant is added to the purified metal solution to form metal salt precipitates (e.g., lithium carbonate, cobalt hydroxide).

The precipitates are dehydrated and washed in a centrifuge to obtain high-purity metal salt powder.

Cathode Material Regeneration

The metal salt powder is mixed with lithium salt in a predetermined ratio, blended with a binder, and then processed by spray drying to produce precursor powder.

The precursor is sintered in a high-temperature sintering furnace at 700–900℃ in an oxygen atmosphere to form cathode materials with a stable lattice structure (e.g., NCM811, LFP).

The sintered materials are crushed and sieved to obtain cathode powder that meets the requirements for battery production.