Raw Material Feeding Organic materials are conveyed to the feeding hopper via a conveyor. The feeding port is designed with anti-spillage and deodorization features to adapt to the processing of high-moisture organic materials.

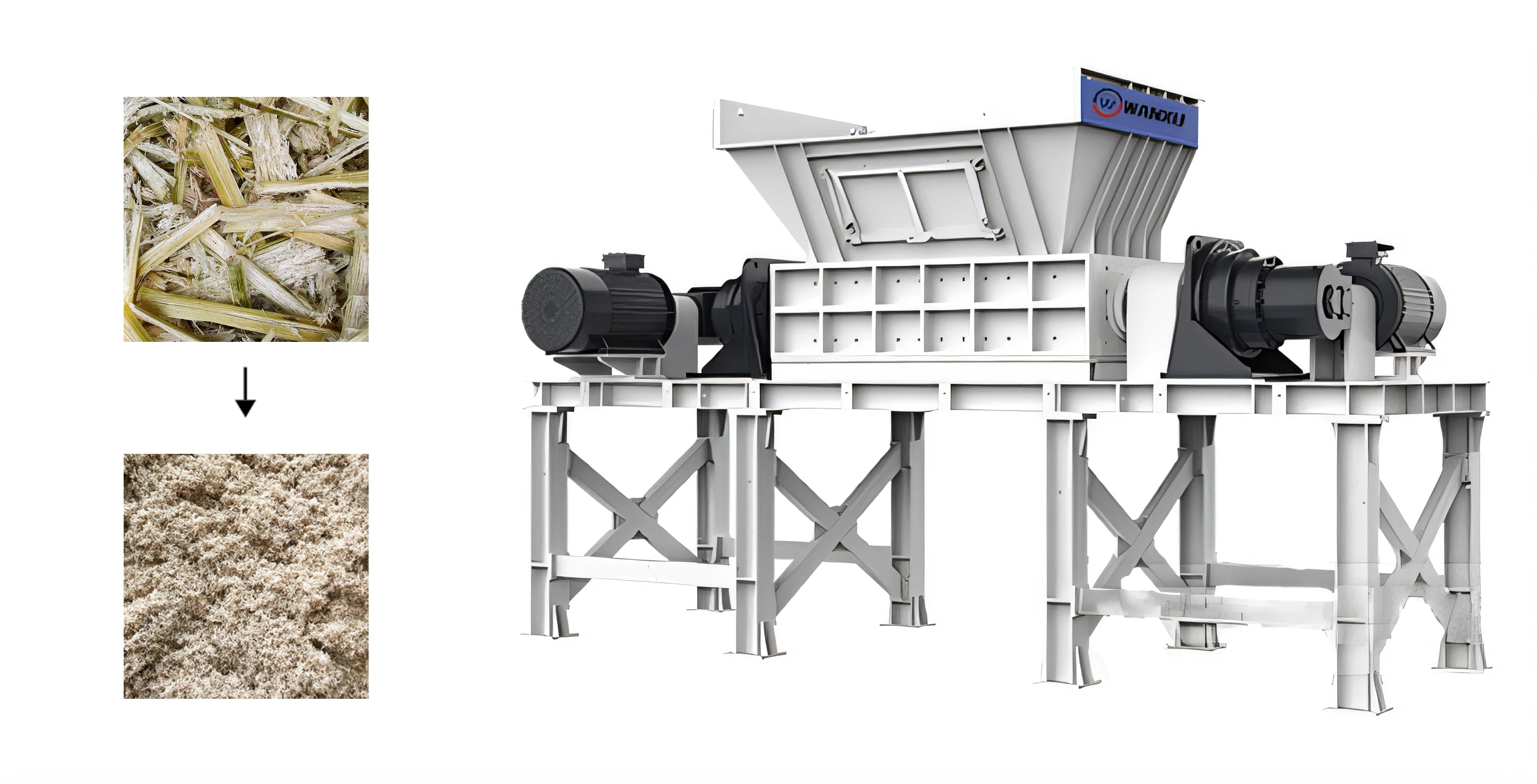

Core Shredding

Driven by dual motors, the two cutter shafts rotate in opposite directions at a low speed with the spiral claw blades meshing with each other. They clamp, shear and tear the organic materials squeezed into the shearing cavity, crushing them into small pieces of preset specifications (the standard discharge size is 20-100mm, achievable by adjusting the blade gap or replacing the blades). The blades are coated with an anti-adhesion layer, and the cutter box is sealed against leakage, which prevents liquid leakage and adhesion of high-moisture organic materials to the cutter shafts. In addition, the blade teeth are detachable and easy to replace, reducing maintenance costs.

Finished Product Discharging

The uniformly shredded organic scraps fall onto the discharge conveyor by the thrust of the rotating cutter shafts and the gravity at the equipment's discharge port, and are directly conveyed to subsequent processing links (fermenters, fertilizer production lines, incinerators, etc.).