Feeding and Preprocessing Waste metal raw materials (including scrap steel, scrap iron, scrap aluminum, thick-walled metal pipes, metal offcuts and others) are conveyed to the front end of the production line via apron conveyors/grab cranes, then fed to manual/intelligent sorting stations where non-metallic impurities mixed in the raw materials such as plastics, wood and rubber are removed. Meanwhile, easily entangled materials like iron wires and cables are separated out to prevent machine jamming and cutter damage in the subsequent shredding process.

Raw Material Preprocessing

For large and irregular waste metal parts (such as waste metal frames and large mechanical housings), hydraulic shears/metal balers are used for shearing and baling to reduce the raw materials to specifications suitable for the feed inlet of the shredder (usually ≤800mm). High-hardness metal parts (such as thick-walled steel pipes and steel castings) require no additional processing and are directly sent to the next process, ensuring smooth feeding of the shredder.

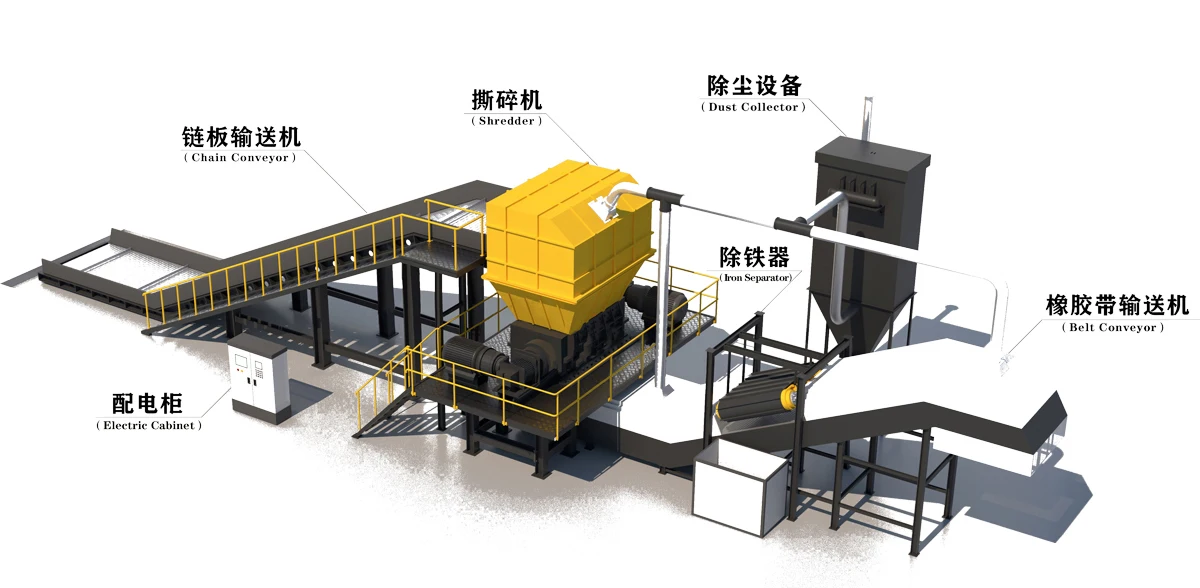

Core Shredding Operation

The preprocessed raw materials are conveyed uniformly into the shredder via a conveyor. Driven by the extrusion-shearing and tearing forces generated by the high-speed meshing of the moving and fixed blades inside the main unit, the waste metal is shredded into metal scraps of preset specifications (the standard discharge size is 50-200mm, and the blade gap can be adjusted as required).

Screening and Classification

The shredded metal particles are sorted by size. Oversized metal materials that fail to meet the shredding standards are removed and conveyed back to the shredder via a conveyor for secondary shredding, ensuring a uniform discharge size.

Supporting Auxiliary Processe

Dust Removal and Noise Reduction

The production line is equipped with bag-type dust collectors throughout the entire process to capture metal dust generated during shredding and screening. Meanwhile, sound insulation enclosures are installed around the shredders and conveyors to meet the environmental protection and noise reduction requirements. Lubrication

Automatic lubrication devices are fitted at the tool transmission parts of the shredders, which fill lubricating oil at a fixed time and quantity to reduce equipment wear. Intelligent Control

The entire production line is centrally controlled by a PLC automatic control system, enabling remote operation, feeding speed adjustment and equipment fault alarm, thus minimizing manual intervention throughout the process.